This month’s (or two month’s) edition of Wiring Harness News had a good article written by Anixter on “Thermoplastic vs Thermoset Wire and Cable Materials.” Since we highlighted this subject last month, we thought we’d give you some more information.

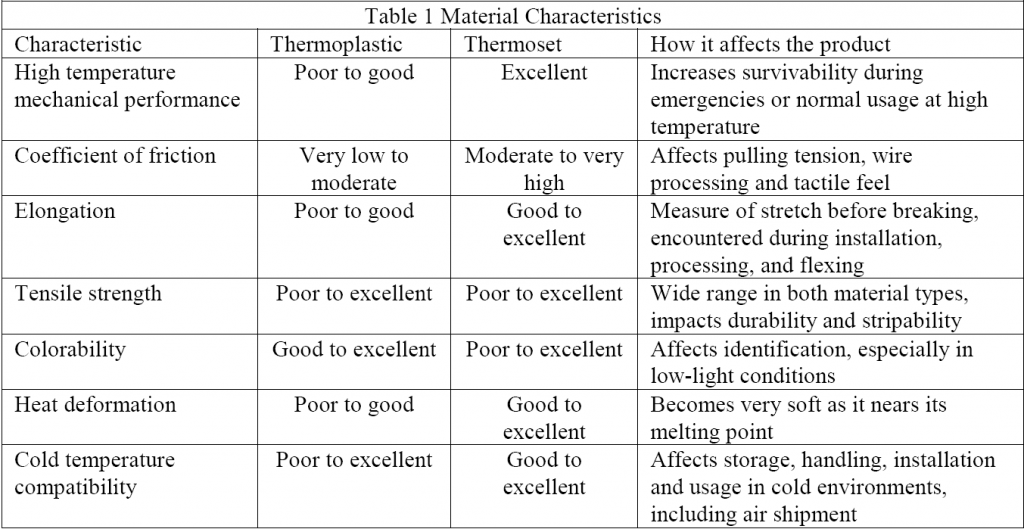

Firstly, Anixter created a nice reference graph listing general characteristics of the two material types and their implications to users:

“The variety of materials available to modern wire and cable manufacturers is immense. This results in a wide range of properties within each material type. The table is a generalized summary that does not apply to every material. It is important to understand how the properties impact the performance of the product in the intended application. Generally speaking, within a given material type, the old adage, “You get what you paid for,” still applies.”

Aside from describing the main characteristics of the two materials, which we did in our original post, they offer some thoughts in response to the question of how do I choose a material for my application?

“Knowing that the key difference between a thermoplastic and thermoset is in the way they respond to elevated temperatures can be an important aspect of which material to choose. For example, thermoset materials are often chosen for circuits that may experience and overload. This is because thermoset materials have a reduced likelihood of failure if momentarily operated at the higher temperatures that often accompany an overloaded conductor. Comparatively, thermoplastics are often easier to strip, which makes them easier to process on automated equipment for large volume applications.”

Some great additions, thanks to Anixter.

See the most up-to-date information with the latest market data available.

Learn More