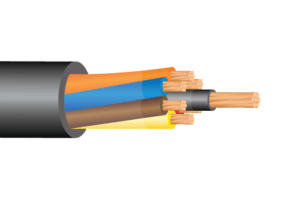

Stranded copper conductors (ASTM B-8), polyvinyl chloride (PVC) insulated, jacketed in nylon for moisture and heat resistance. Phase identified and cabled together with fillers and/or binders as required. Cabled core is covered with an overall black PVC jacket that is gas and oil resistant. Jacket available in colors. Suitable for use in hazardous locations: Class 1 and 2, Division 2.

Concentric 19 strand soft drawn annealed copper per UL and ASTM requirements. Tinned conductors and other stranded configurations are available upon request. Single conductors are Oil & Gas Resistant I.

Concentrically applied PVC insulation with a Nylon jacket. Rated at 90°C dry and 75°C wet. 16-18 AWG TFFN wire only, 10-14 AWG THHN only.

A black, flame resistant, Polyvinyl Chloride (PVC) jacket is extruded over the assembly. The surface profile shall approximate that of the interior assembly.

The wire shall be identified by surface marking indicating the manufacturer, conductor size, voltage rating, UL symbol, and type designation. Custom lengths, color, and packaging is available by request.

KRIS-TECH WIRE XX AWG XX CONDUCTOR E515926 (UL) TC-ER THHN 600V 90°CWET/DRY PVC JACKET SUN RES FT4 OIL RES I DIR BUR “ROHS” MADE IN USAVALUE

| AWG | Number of Conductors | Jacket Thickness (mils) | Nominal Diameter over Jacket (inches) | Approx. Net Weight (Lbs/Mft) |

|---|---|---|---|---|

| 18 | 2 | 45 | 0.26 | 30 |

| 18 | 3 | 45 | 0.27 | 40 |

| 18 | 4 | 45 | 0.30 | 50 |

| 18 | 5 | 45 | 0.32 | 59 |

| 18 | 6 | 45 | 0.36 | 69 |

| 18 | 7 | 45 | 0.35 | 89 |

| 18 | 9 | 45 | 0.40 | 112 |

| 18 | 10 | 45 | 0.44 | 121 |

| 18 | 12 | 45 | 0.44 | 156 |

| 18 | 16 | 45 | 0.49 | 211 |

| 18 | 19 | 60 | 0.55 | 220 |

| 18 | 25 | 60 | 0.64 | 279 |

| 18 | 30 | 60 | 0.70 | 290 |

| 18 | 48 | 80 | 0.86 | 459 |

| AWG | Number of Conductors | Jacket Thickness (mils) | Nominal Diameter over Jacket (inches) | Approx. Net Weight (Lbs/Mft) |

|---|---|---|---|---|

| 16 | 2 | 45 | 0.29 | 38 |

| 16 | 3 | 45 | 0.30 | 53 |

| 16 | 4 | 45 | 0.33 | 65 |

| 16 | 5 | 45 | 0.36 | 78 |

| 16 | 7 | 45 | 0.39 | 102 |

| 16 | 9 | 45 | 0.45 | 128 |

| 16 | 10 | 45 | 0.50 | 143 |

| 16 | 12 | 45 | 0.50 | 164 |

| 16 | 16 | 60 | 0.59 | 226 |

| 16 | 19 | 60 | 0.62 | 261 |

| 16 | 20 | 60 | 0.65 | 275 |

| 16 | 25 | 60 | 0.73 | 337 |

| 16 | 50 | 80 | 0.96 | 660 |

| AWG | Number of Conductors | Jacket Thickness (mils) | Nominal Diameter over Jacket (inches) | Approx. Net Weight (Lbs/Mft) |

|---|---|---|---|---|

| 14 | 2 | 45 | 0.28 | 53 |

| 14 | 3 | 45 | 0.33 | 75 |

| 14 | 4 | 45 | 0.36 | 95 |

| 14 | 5 | 45 | 0.40 | 115 |

| 14 | 7 | 45 | 0.43 | 152 |

| 14 | 9 | 45 | 0.50 | 193 |

| 14 | 10 | 60 | 0.59 | 230 |

| 14 | 12 | 60 | 0.59 | 265 |

| 14 | 13 | 60 | 0.62 | 285 |

| 14 | 16 | 60 | 0.65 | 341 |

| 14 | 19 | 60 | 0.69 | 396 |

| 14 | 25 | 60 | 0.82 | 514 |

| 14 | 30 | 80 | 0.89 | 635 |

| 14 | 37 | 80 | 0.95 | 766 |

| 14 | 40 | 80 | 0.99 | 823 |

| AWG | Number of Conductors | Jacket Thickness (mils) | Nominal Diameter over Jacket (inches) | Approx. Net Weight (Lbs/Mft) |

|---|---|---|---|---|

| 12 | 2 | 45 | 0.31 | 72 |

| 12 | 3 | 45 | 0.38 | 103 |

| 12 | 4 | 45 | 0.41 | 131 |

| 12 | 5 | 45 | 0.45 | 159 |

| 12 | 7 | 45 | 0.49 | 213 |

| 12 | 9 | 60 | 0.60 | 287 |

| 12 | 10 | 60 | 0.67 | 319 |

| 12 | 12 | 60 | 0.67 | 370 |

| 12 | 16 | 60 | 0.74 | 479 |

| 12 | 19 | 60 | 0.78 | 560 |

| 12 | 25 | 80 | 0.98 | 762 |

| AWG | Number of Conductors | Jacket Thickness (mils) | Nominal Diameter over Jacket (inches) | Approx. Net Weight (Lbs/Mft) |

|---|---|---|---|---|

| 10 | 2 | 45 | 0.36 | 106 |

| 10 | 3 | 45 | 0.45 | 154 |

| 10 | 4 | 45 | 0.49 | 198 |

| 10 | 5 | 60 | 0.57 | 257 |

| 10 | 6 | 60 | 0.62 | 302 |

| 10 | 7 | 60 | 0.62 | 343 |

| 10 | 9 | 60 | 0.73 | 435 |

| 10 | 10 | 60 | 0.81 | 485 |

| 10 | 12 | 60 | 0.81 | 565 |

| 10 | 16 | 80 | 0.94 | 770 |

| 10 | 40 | 80 | 1.38 | 1801 |