Editor’s Note: This article was developed by Brian Prusinski, with additional research by Gino Geruntino.

The shortest distance from Point A to Point B is a straight line, but that isn’t always the case – especially when installing wire and cable.

Sometimes, wire has to bend to connect machines and other equipment to power supplies. That means running wire or cable along poles, up walls, across cable trays, and around corners to get from one point to another. And while it might seem simple, safely installing cable means not bending it too much or too often.

As with any potentially dangerous situation, several questions must be answered before jumping in. How tightly can the copper or aluminum wire safely bend in an installation? What guidelines do we need to follow, and how can we prevent damage in the first place?

Although every wire is different, there are general guidelines to help workers safely run power through homes, businesses, and industrial locations.

Simply put, a minimum bend radius is how tightly you can bend a wire or cable without damaging it or compromising its mechanical and electrical performance.

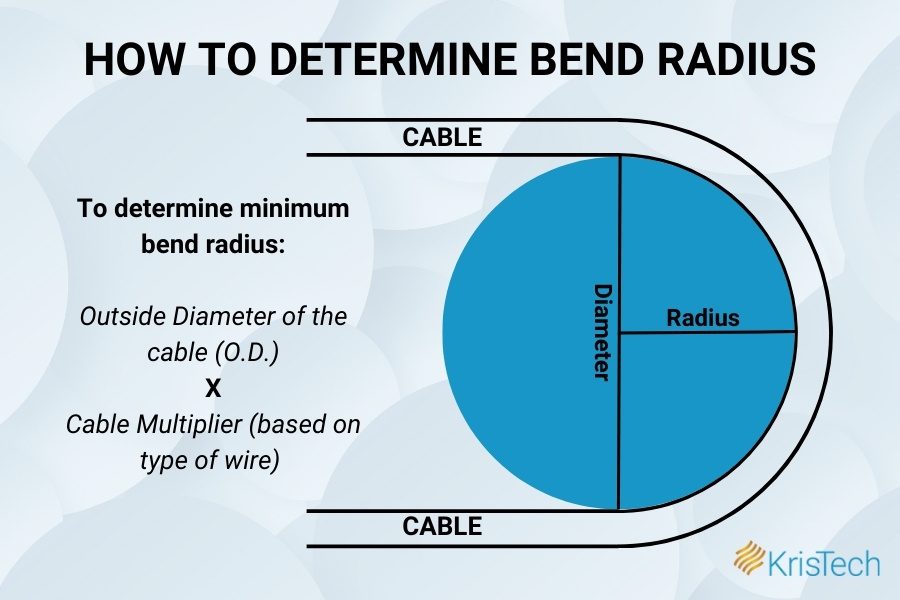

The bend radius is the radius of the circular curve made (radius) when you bend a wire back onto itself. To determine the bend radius, you must know the OVERALL cable diameter. Typically, this information is on the manufacturer’s spec sheet and varies based on cable type, insulation, and conductor count. Thicker cables have a larger minimum bend radius than smaller ones, and more conductors bend less than a single conductor.

Once you know the outside diameter, you can use the formula below to find the minimum bend radius.

Minimum Bend Radius = Outside Diameter of the cable (O.D.) x Cable Multiplier (based on type of wire)

Bend radius isn’t limited to wire and cable installs, either. Pipes, hoses, and other products have similar safety measures to prevent damage.

Wire size is only one of several variables used to determine bend radius. Both controlled and uncontrolled factors may impact how the wire reacts in its environment.

Bend radius changes based on the type of metal used and how the conductors are fashioned. For example, aluminum has a smaller bend radius than copper because it is more malleable. Stranded wire typically bends more than a single solid conductor.

The higher the temperature, the more the wire or cable will bend. The opposite is true when the temperature drops, making the wire more rigid.

In the same way a bicycle has a much smaller turn radius than a tractor-trailer, so does a smaller gauge wire compared to a larger gauge one.

Large wires have larger bend radii because there is more mass to move. Smaller wires are thinner, making them more posable, thus allowing them to have a tighter bend radius.

The wire may be more or less rigid based on the insulation used. Shielding materials like copper tape or metal-clad protection limit how much the wire can move, preventing the same range of motion you might get from a standard plastic-type insulation or jacketing material.

There isn’t one answer because different rules may apply based on the product and materials used.

Wire and cable guidelines and regulations are governed by the National Fire Protection Association (NFPA) and the National Electrical Code (NEC). Within the NEC regulations, different wire types fall under different sets of rules, which you can see in the table below:

| Wire or Cable Type | Aluminum | Copper |

| Single or multiple-conductor cables without metallic shielding, >1,000 V | 12 times the overall cable diameter | 8-10 times the overall cable diameter |

| Single-conductor cables with shielding, >1,000 V | 16 times the overall cable diameter | 12 times the overall cable diameter |

| Multiconductor cables with individually shielded conductors, >1,000 V | 16 times the individual conductor diameter or 10 times the overall cable diameter — whichever is greater | 12 times the individual conductor diameter or 7 times the overall cable diameter — whichever is greater |

Now that we know how much the wire can bend, we need to know how much it should.

Like the rules related to wire bend radii, there are rules tied to how many times the wire can bend in an installation. According to the NEC, the total bend in a continuous run is limited to 360 degrees.

“There shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, for example, conduit bodies and boxes.”

Wire installations aren’t always perfect, and workers may try to get too much out of the cable by bending it past its limits to make it fit somewhere.

While tightly wrapping the wire around a pole or sending it through a long and winding raceway may seem like a good idea, it sets the stage for problems to occur, including:

Damaged conductors create an arc risk if anyone or anything is unlucky enough to come into contact with them. Arcs can also potentially start electrical fires, damaging other things around them.

When cracks form in an electrical wire’s insulation, they can lead to dangerous electrical shocks and short circuits that can cause severe burns, heart attacks, and even death.

If the wire or cable radius is tighter or smaller than the spec allows, undue force pushes the copper, aluminum, or fiber optic core out of the center. This may impact the signal or electrical transmission. The conductor or core must remain in the center of the insulation, creating eccentricity and maximizing performance.

The jacketing used in tray cable is critical to protecting conductors from damage inside conduits and trays. When the jacket is damaged, it can alter the cable’s current flow, leading to lost continuity and increased electromagnetic interference, or EMI.

In some cases, damaged wire can LOSE flexibility over time. If you bend it too much and too often, the cable eventually becomes harder to work with and less efficient.

A terrible diet and lack of exercise can shorten our lifespans. Too much bending can cause wire damage, resulting in failures sooner than anticipated.

They might seem like a lot of rules about nothing, but licensed electricians will tell you that understanding the NEC’s guidelines is critical to maintaining safe environments.

Before installing any wire, know what the bend radius is. It will help avoid overbending and reduce cable stress.

Also, don’t yank on the wire or pull it through the conduit without using a high-quality cable lubricant. Lubricants make pulling cable easier and faster while reducing friction and limiting abrasion damage while going around corners. Depending on the situation, one of several types of lubricants are available.

And finally, if you have any questions about the wire and cable used during a project, ASK. Distributors and manufacturers are great knowledge bases to lean on to learn more about the wire, its specifications, and how best to use it to meet specific requirements. They are a trusted resource to help the project move along seamlessly.

Knowing the NEC regulations, adhering to them, and ensuring others do the same can extend the usable lifespan of the wire and reduce the risk of injury, fires, and other mishaps.

If questions arise, rely on the wire manufacturer or distributor to help you make an informed decision. It could be the difference between a safe and efficient project or eventual failure.